How to Manage Supply Chain Efficiently Using Logistics Software

Managing supply chains manually leads to delays and rising costs. Learn how logistics software improves visibility, efficiency, and control across supply chain operations.

How to Manage Supply Chain Efficiently Using Logistics Software

For many businesses, supply chain inefficiencies don’t appear suddenly. They build slowly—missed delivery timelines here, excess inventory there, rising freight costs somewhere else. Individually, these issues seem manageable. Collectively, they signal a deeper problem: the supply chain has outgrown the systems managing it.

To manage supply chain operations efficiently, businesses need more than operational effort or experienced teams. They need structure, visibility, and coordination at scale. This is exactly where logistics software becomes a foundational capability rather than a “tool.”

This article explains how logistics software fundamentally changes the way supply chains operate, not just by automating tasks, but by reshaping decision-making, execution, and long-term scalability.

The Hidden Cost of Manual Supply Chain Operations

Most supply chains don’t start broken. They start simple.

A few suppliers. One warehouse. Limited shipments. At this stage, spreadsheets and emails work. But growth introduces complexity at an exponential rate. More suppliers mean more lead times. More orders mean tighter delivery windows. More regions mean more carriers, documents, and compliance requirements.

Manual systems fail not because teams are inefficient, but because information becomes fragmented.

When inventory data sits in one file, shipment updates in another, and delivery confirmations arrive by phone or email, no one has a complete picture. Decisions are made late. Problems are discovered after they impact customers. Costs rise quietly until margins start shrinking.

This is the operational reality logistics software is designed to fix.

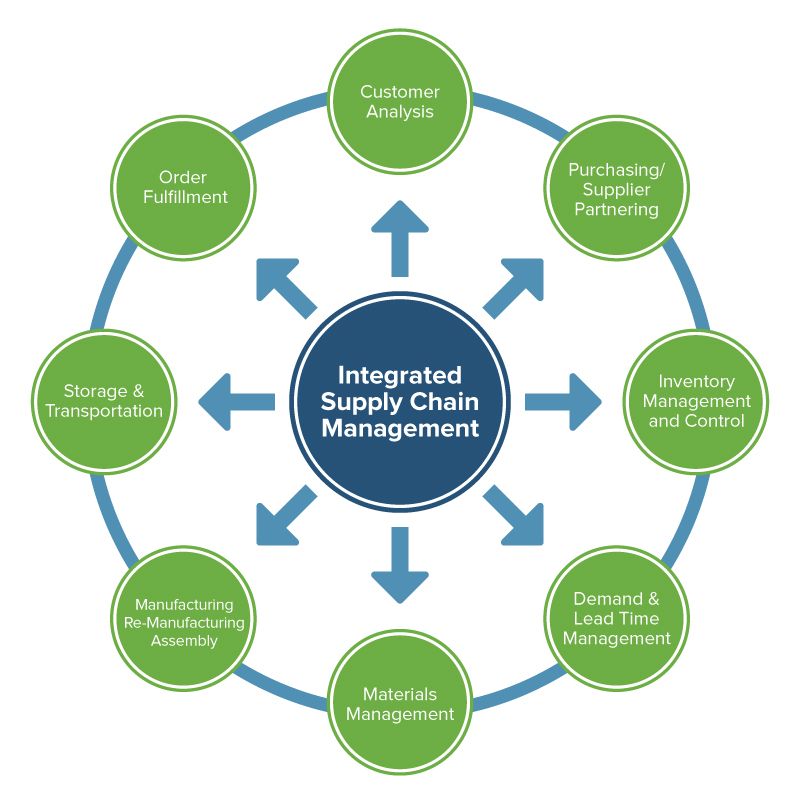

Logistics Software as the Backbone of Modern SCM Management

Logistics software does not replace supply chain strategy. It enables it.

From an SCM management perspective, the role of logistics software is to connect planning assumptions with real-world execution. It turns forecasts into movements, plans into deliveries, and data into decisions.

At a strategic level, logistics software provides:

A single source of truth across supply chain activities

Real-time feedback loops between planning and execution

Measurable performance across suppliers, warehouses, and transport

Without this backbone, supply chain management remains theoretical.

From Fragmentation to Flow: How Logistics Software Reshapes Operations

Efficient supply chains are not built on speed alone. They are built on flow—the smooth movement of goods, information, and decisions across every stage.

Logistics software creates this flow by eliminating operational silos. Procurement teams, warehouse managers, transport coordinators, and leadership all operate on the same data foundation. When one part of the system changes, the rest adapts automatically.

This interconnectedness is what allows supply chains to remain stable even under pressure.

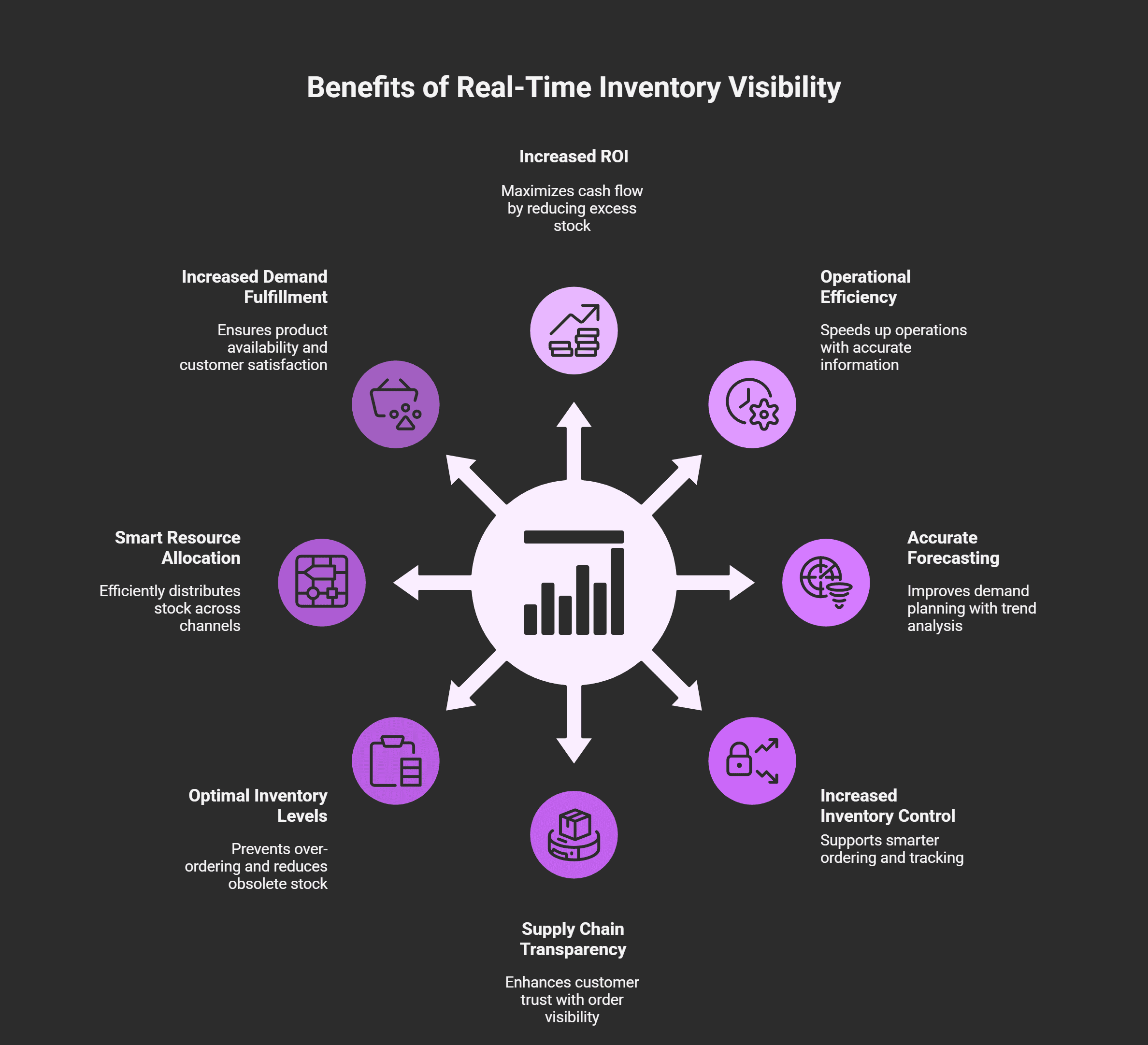

Inventory Control: Moving From Guesswork to Precision

Inventory is where inefficiency hides most easily. Excess stock rarely feels like a problem—until capital is locked, storage costs rise, and slow-moving goods pile up. On the other hand, stockouts damage customer trust instantly.

Logistics software enables a more disciplined approach to inventory management by combining:

Real-time stock visibility

Demand trend analysis

Movement-based replenishment logic

Instead of reacting to shortages, businesses can anticipate demand shifts and position inventory accordingly.

This shift—from reactive stocking to predictive planning—is one of the most immediate efficiency gains logistics software delivers.

Transportation Efficiency Beyond Cost Cutting

Transportation inefficiency is often misunderstood as a pricing problem. In reality, it is usually a coordination problem.

When shipments are planned without visibility into inventory readiness, carrier availability, or route constraints, businesses resort to last-minute decisions. These decisions cost more and deliver less reliability.

Logistics software improves transportation efficiency by synchronizing it with upstream and downstream activities. Routes are planned based on real dispatch readiness. Loads are optimized based on actual demand. Delays are flagged before they cascade.

The result is not just lower freight cost—but more predictable delivery performance.

Order Fulfilment as a System, Not a Task

Order fulfilment is often treated as a warehouse function. In reality, it is a cross-functional process that touches inventory accuracy, transport readiness, and customer communication.

Logistics software turns fulfilment into a coordinated system. Orders flow automatically into warehouse operations. Picking and packing align with dispatch schedules. Delivery updates are communicated in real time.

This orchestration ensures that higher order volumes do not degrade service quality—a critical requirement for scaling businesses.

Visibility: The Difference Between Control and Chaos

Perhaps the most transformative impact of logistics software is visibility.

Without visibility, supply chain teams operate in a constant state of uncertainty. Problems are discovered too late. Decisions are defensive. Growth feels risky.

With visibility, supply chains become manageable systems.

End-to-end visibility allows leaders to:

Monitor performance across the entire supply chain

Identify bottlenecks before they escalate

Make confident decisions backed by data

This is where logistics software shifts from operational tool to strategic asset.

Scaling Without Breaking the Supply Chain

Growth is where weak systems collapse.

Many businesses grow revenue faster than operational capability. Orders increase, but processes don’t evolve. Teams work harder, not smarter. Eventually, service quality declines.

Logistics software enables scalable efficiency. Processes remain stable even as volume increases. Automation absorbs complexity. Data replaces assumptions.

This is what allows businesses to grow without sacrificing reliability.

When Logistics Software Delivers the Highest ROI

Logistics software creates the most impact when:

Supply chains involve multiple suppliers or locations

Shipment volumes are growing rapidly

Inventory accuracy directly affects revenue

Customer expectations are time-sensitive

In these environments, manual coordination becomes a bottleneck rather than a solution.

Final Perspective

To manage supply chain operations efficiently, businesses must move beyond effort-based execution and adopt system-based coordination. Logistics software provides the structure that modern supply chains require—connecting planning, execution, and insight into a single operational framework.

As complexity increases, the question is no longer whether to adopt logistics software, but how early.

Let’s Move Your Business Forward.

Fast, reliable, and customized logistics solutions at your fingertips.