Logistics Management and Supply Chain Management: Understanding the Real Difference

Many businesses use logistics management and supply chain management interchangeably. This in-depth guide explains their differences, roles, real-world examples, and why understanding both is critical for growth.

Logistics Management and Supply Chain Management: Understanding the Real Difference

In the logistics and trade industry, few terms are used as loosely—and misunderstood as deeply—as logistics management and supply chain management. Many businesses assume they are the same thing. Others believe logistics is just transportation and supply chain management is only for large enterprises.

In reality, logistics management and supply chain management are closely connected but fundamentally different in purpose, scope, and impact. Understanding this difference is not just theoretical—it directly affects cost control, delivery performance, customer satisfaction, and long-term scalability.

This article breaks down the difference in a practical, easy-to-understand way, using real examples from freight movement, warehousing, and trade operations.

Why This Confusion Exists in the First Place

The confusion usually begins at the operational level. Most businesses interact with logistics first—booking transport, storing goods, dispatching orders. These activities are visible, measurable, and immediate.

Supply chain management, on the other hand, often works behind the scenes. It deals with planning, forecasting, supplier coordination, and system design. Because its impact is indirect, many companies don’t recognize it as a separate function until problems start appearing.

When delays increase, costs rise, or inventory becomes unpredictable, businesses realize that execution alone is not enough. That’s when the distinction between logistics management and supply chain management becomes clear.

What Supply Chain Management Really Means

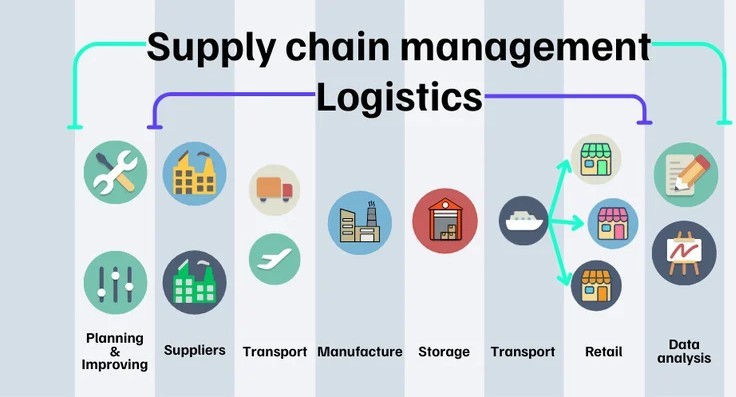

Supply chain management (SCM) is the strategic function responsible for designing and controlling how goods move from source to customer.

It is not limited to logistics. Instead, it connects multiple business functions into a single coordinated system.

Supply chain management looks at the big picture:

Where should suppliers be located?

How much inventory should be held at each stage?

How do seasonal demand changes affect production and transport?

What risks exist if a supplier or route fails?

These decisions shape how logistics will operate later. A poorly planned supply chain creates pressure on logistics teams, no matter how efficient they are.

What Logistics Management Actually Handles

Logistics management focuses on turning supply chain plans into real-world action.

It is responsible for:

Moving goods between locations

Storing inventory safely and efficiently

Ensuring orders are picked, packed, and delivered correctly

Managing timelines, freight costs, and service quality

Logistics management operates in real time. Every delay, error, or miscommunication is immediately visible to customers.

Even the best supply chain strategy will fail if logistics execution is weak. That’s why logistics is often described as the backbone of daily operations.

How Logistics Chain Management Fits In

Logistics chain management refers to how logistics activities are connected across the supply chain.

It ensures that:

Goods flow smoothly between suppliers, warehouses, and customers

Information is shared between transporters, warehouses, and operations teams

Delays at one stage do not disrupt the entire chain

In modern operations, logistics chain management relies heavily on coordination, visibility, and system integration rather than manual follow-ups.

A Practical Comparison: Strategy vs Execution

Instead of listing many short points, let’s look at how these functions differ in real business terms.

Aspect | Supply Chain Management | Logistics Management |

|---|---|---|

Core Role | Strategic planning and coordination | Operational execution |

Focus Area | Long-term efficiency and resilience | Daily movement and delivery |

Scope | End-to-end business flow | Transport, warehousing, fulfillment |

Decision Level | Management and leadership | Operations and execution teams |

Time Horizon | Months and years | Hours and days |

This difference explains why companies often improve logistics performance but still struggle with costs and delays—the root cause lies in supply chain planning.

Real-World Example: Import and Distribution Business

Consider a company importing consumer goods from overseas.

From a supply chain management perspective, decisions include:

Choosing suppliers based on reliability and lead time

Planning import volumes based on forecasted demand

Deciding warehouse locations to reduce delivery time

Balancing inventory holding costs with service levels

From a logistics management perspective, execution involves:

Booking freight and managing transit schedules

Handling port operations and customs clearance

Transporting goods to warehouses

Delivering orders to distributors or retailers

If supply chain planning is inaccurate, logistics teams face constant firefighting. If logistics execution fails, even the best supply chain strategy collapses.

Why Businesses Struggle When They Focus Only on Logistics

Many growing companies invest heavily in transport and warehouse operations but ignore supply chain planning. Initially, this works. As order volumes increase, cracks begin to appear.

Common issues include:

Overstocking slow-moving items

Running out of fast-moving products

Paying premium freight costs to meet deadlines

Poor coordination between procurement and delivery teams

These are not logistics problems alone. They are supply chain management gaps that surface during logistics execution.

How Technology Connects Logistics and Supply Chain Management

Modern digital platforms have blurred the line between logistics management and supply chain management by connecting them through data.

With the right systems, businesses gain:

End-to-end visibility across inventory and shipments

Better demand forecasting based on historical data

Automated alerts for delays and exceptions

Centralized coordination across teams and partners

This integration allows logistics to operate proactively instead of reactively.

Which Function Should Businesses Prioritize?

The answer depends on maturity, but the sequence matters.

Businesses should:

Design a clear supply chain strategy

Build strong logistics execution capabilities

Connect both through digital systems

Ignoring either side creates imbalance. Strong logistics without strategy leads to inefficiency. Strong strategy without execution leads to failure.

FAQs

1. Is logistics management a part of supply chain management?

Yes. Logistics management is a core component responsible for executing supply chain plans.

2. Can small businesses manage without supply chain management?

They can initially, but growth becomes difficult without structured planning.

3. What is logistics chain management?

It refers to coordinating transportation, warehousing, and delivery across the supply chain.

4. Why is understanding this difference important?

It helps businesses reduce costs, improve delivery performance, and scale sustainably.

Final Thoughts

Understanding logistics management and supply chain management is not about definitions—it’s about alignment. When planning and execution work together, businesses gain control, visibility, and resilience.

In today’s competitive logistics landscape, companies that master both are the ones that grow confidently and sustainably.

Let’s Move Your Business Forward.

Fast, reliable, and customized logistics solutions at your fingertips.