Supply Chain Logistics Management: Processes, Challenges, and Practical Solutions

Supply chain logistics management connects planning with execution. Learn its meaning, core processes, real-world challenges, and practical solutions businesses use to improve efficiency and control costs.

Supply Chain Logistics Management: Processes, Challenges, and Practical Solutions

As businesses grow and customer expectations rise, managing the movement of goods becomes far more complex than simply shipping products from one location to another. This is where supply chain logistics management plays a critical role.

Supply chain logistics management acts as the bridge between planning and execution. It ensures that strategic supply chain decisions—such as sourcing, inventory levels, and distribution strategy—are executed smoothly through logistics operations.

In this guide, we’ll break down what supply chain logistics management really means, how it works in real operations, the challenges businesses face, and the solutions that help modern companies stay competitive.

Understanding Supply Chain Logistics Management

Supply chain logistics management refers to the coordinated management of logistics activities across the entire supply chain. It does not operate in isolation. Instead, it aligns logistics execution with supply chain planning.

This function ensures that:

Goods move according to demand forecasts

Inventory is positioned at the right locations

Transportation aligns with cost and service goals

Delivery timelines meet customer expectations

Without this alignment, even well-planned supply chains suffer from delays, excess costs, and operational chaos.

Why Supply Chain Logistics Management Is So Important

In many businesses, logistics is treated as a support function. In reality, it directly affects revenue, margins, and customer satisfaction.

Poor supply chain logistics management leads to:

Late deliveries

Stockouts or overstocking

High freight costs

Poor visibility across operations

Strong supply chain logistics management, on the other hand, creates predictable, scalable, and resilient operations.

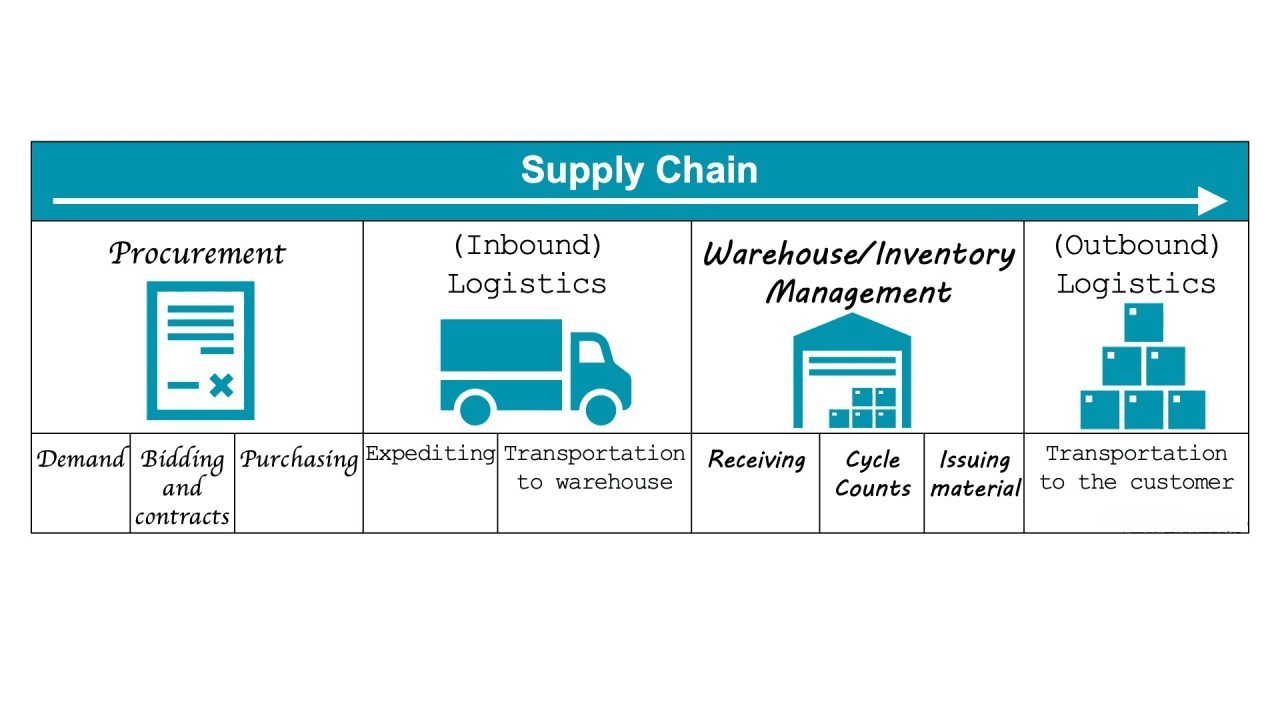

Core Processes in Supply Chain Logistics Management

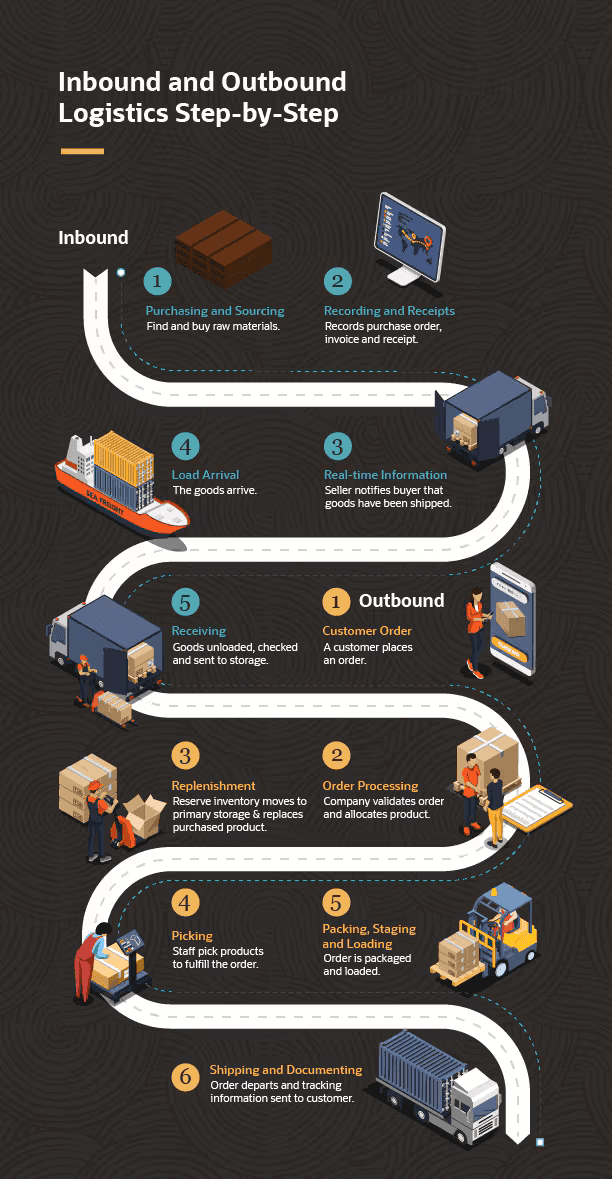

Procurement and Inbound Logistics

The process begins with sourcing goods or raw materials from suppliers. Supply chain logistics management ensures that inbound shipments arrive on time, in the right quantity, and at optimal cost.

This stage involves:

Coordinating supplier dispatch schedules

Planning inbound transport routes

Managing port, customs, or receiving operations

If inbound logistics are poorly managed, delays ripple through the entire supply chain, affecting production and delivery

Inventory and Warehouse Management

Once goods arrive, they must be stored efficiently. Inventory management is not just about storage—it’s about balancing availability with cost.

Effective supply chain logistics management ensures:

Inventory is placed close to demand centres

Stock levels align with forecasted demand

Warehouses operate with minimal handling errors

Poor inventory decisions increase holding costs and reduce responsiveness.

Transportation and Distribution

Transportation is often the most expensive part of logistics. Managing it effectively requires coordination between planning and execution.

This stage includes:

Selecting the right transport modes

Optimizing routes and loads

Managing carrier performance

Monitoring transit times

Supply chain logistics management ensures transportation decisions support both cost efficiency and service reliability.

Order Fulfilment and Last-Mile Delivery

Order fulfilment is where logistics becomes visible to customers. Even a small delay or error at this stage can damage trust.

Effective management focuses on:

Accurate order picking and packing

Real-time delivery tracking

Managing delivery commitments

This is often the most customer-sensitive part of the supply chain.

Reverse Logistics and Returns

Returns are no longer an exception—they are a standard part of operations. Supply chain logistics management ensures returned goods are handled efficiently, minimizing loss and recovering value where possible.

Common Challenges in Supply Chain Logistics Management

Many businesses struggle not because of lack of effort, but due to structural issues.

Lack of Visibility

When shipment status, inventory levels, and delivery timelines are tracked manually or across disconnected systems, decision-making becomes reactive instead of proactive.

This leads to delays being discovered only after customers complain.

Manual and Fragmented Processes

Spreadsheets, emails, and phone calls may work at small scale, but they collapse as volumes increase. Fragmented processes create duplication, errors, and dependency on individuals.

Cost Inefficiencies

Without integrated planning, businesses often rely on last-minute transport decisions, premium freight, or excess inventory to avoid disruptions—all of which increase costs.

Scalability Issues

Processes that work for 50 shipments a month fail at 500. Without structured supply chain logistics management, scaling leads to chaos instead of growth.

Practical Solutions to Strengthen Supply Chain Logistics Management

Rather than quick fixes, businesses need systematic solutions.

Process Standardization

Defining clear workflows for procurement, warehousing, transport, and delivery reduces confusion and dependency on individuals.

Centralized Visibility

Having a single view of inventory, shipments, and orders allows teams to identify issues early and act before disruptions escalate.

Technology Integration

Modern platforms connect planning with execution by integrating:

Inventory systems

Transport management

Order processing

Analytics and reporting

This creates a connected supply chain rather than isolated operations.

Who Benefits Most from Supply Chain Logistics Management?

Supply chain logistics management is valuable for:

Growing logistics companies

Importers and exporters

Manufacturers and distributors

E-commerce and retail businesses

Any organization handling complex product flows benefits from better coordination and visibility.

Final Thoughts

Supply chain logistics management is not just an operational function—it is a strategic capability. Businesses that manage it well gain control over costs, timelines, and customer experience.

As markets grow more competitive, success will belong to companies that connect planning with execution and build logistics systems designed to scale.

Let’s Move Your Business Forward.

Fast, reliable, and customized logistics solutions at your fingertips.